Universal testing machines

Universal Testing Machines can conduct a wide variety of tests, catering to the diverse needs of industries such as aerospace, automotive, construction, and materials science.

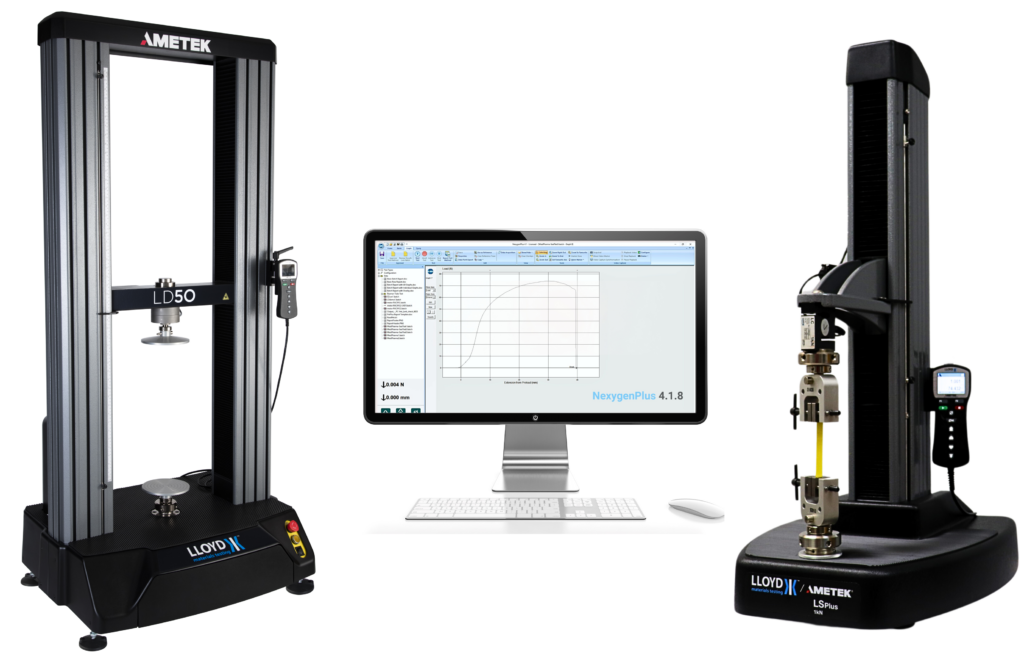

We offer a full range of Universal Testing Machines

- For lower force up to 5 kN we can provide Lloyd Instruments LS series testers, more info here >

- For force up to 100 kN we can provide Lloyd Instruments LD series machines , more info here >

- Here also more information about the NexygenPlus materials testing software >

Here are some of the key tests performed by UTMs

Tensile Testing

- What it does: Measures the force required to pull a material until it breaks. This test determines a material’s tensile strength, elongation, and modulus of elasticity.

- Applications: Used for metals, plastics, textiles, wires, and composites to ensure they meet the required strength specifications for their intended use.

Compression Testing

- What it does: Applies a compressive force to materials to determine their behavior under compression. It assesses compressive strength, yield strength, and the modulus of elasticity under compression.

- Applications: Critical for materials like concrete, foam, and metals used in structural applications, packaging, and automotive components.

Flexural/Bending Testing

- What it does: Applies a bending force to a sample to evaluate its flexural strength and modulus. This test is essential for understanding how a material behaves under bending or flexural stress.

- Applications: Important for materials used in beams, pipes, and plastic components where bending resistance is crucial.

Shear Testing

- What it does: Measures the material’s ability to resist forces that can cause the material’s internal layers to slide against each other.

- Applications: Useful for adhesives, composites, and metal alloys where shear strength is a key property for their application.

Peel Testing

- What it does: Assesses the adhesive strength of bonded materials by measuring the force required to peel one material away from another at a specific angle.

- Applications: Widely used in packaging, laminates, and bonded structures to ensure the integrity of adhesive joints.

Tear Testing

- What it does: Determines the force required to continue the tearing of an initial cut in sheet materials.

- Applications: Essential for materials like textiles, plastics, and paper where tear resistance is important for the product’s durability.

Creep Testing

- What it does: Measures the deformation of a material over time under a constant load at a constant temperature.

- Applications: Important for materials used in high-temperature environments, such as metals in engine parts or plastics in electronics, to ensure long-term performance.

These tests, among others, allow UTMs to be versatile tools in the evaluation, development, and quality control of materials and products across various industries.